Flexible Packaging for Food: More Than Just Retail

Whether they need to keep products shelf-stable, ready for reheating, or ready for rehydration, businesses have looked to flexible packaging more and more in recent years to transport, protect, and dispense their food products.

When thinking of food packaging, many people envision eye-catching pouches and bags from our favorite grocery stores, and honestly, it’s fun to see retail packaging running on our machines.

But did you know that at Heritage Packaging we are best equipped to provide food packaging for military rations, interplant transport, institutional use, and secondary food packaging? Though not as glamorous, these sectors are equally as important in keeping our food safe for consumption.

In this blog we’ll explore what food processing plants, businesses, and organizations with food products need to consider before purchasing food packaging. We’ll explain why Safe Quality Food-certified companies are so important to the food industry, and we’ll walk you through what our custom process looks like so you can get a good idea of whether or not a custom packaging product is right for your food product.

Let’s start by diving into the different uses for food packaging that we encounter at Heritage Packaging!

Uses for Food Packaging

Retail packaging is used to display branding and graphics and to keep food shelf-stable. At Heritage Packaging, we provide custom retail packaging solutions to applications with volumes that reach as many as 5-6 million pieces annually. Pouches with fitments are our specialty!

Beyond those quantities, you may be better served by one of our colleagues in the industry with a different complement of equipment. If we’re not the best fit, we are always happy to guide you in the right direction. Retail packaging is seen on store shelves or sold directly to consumers, but what about food that is sold in bulk, served in a cafeteria or restaurant, and food that requires long-term storage or rehydration?

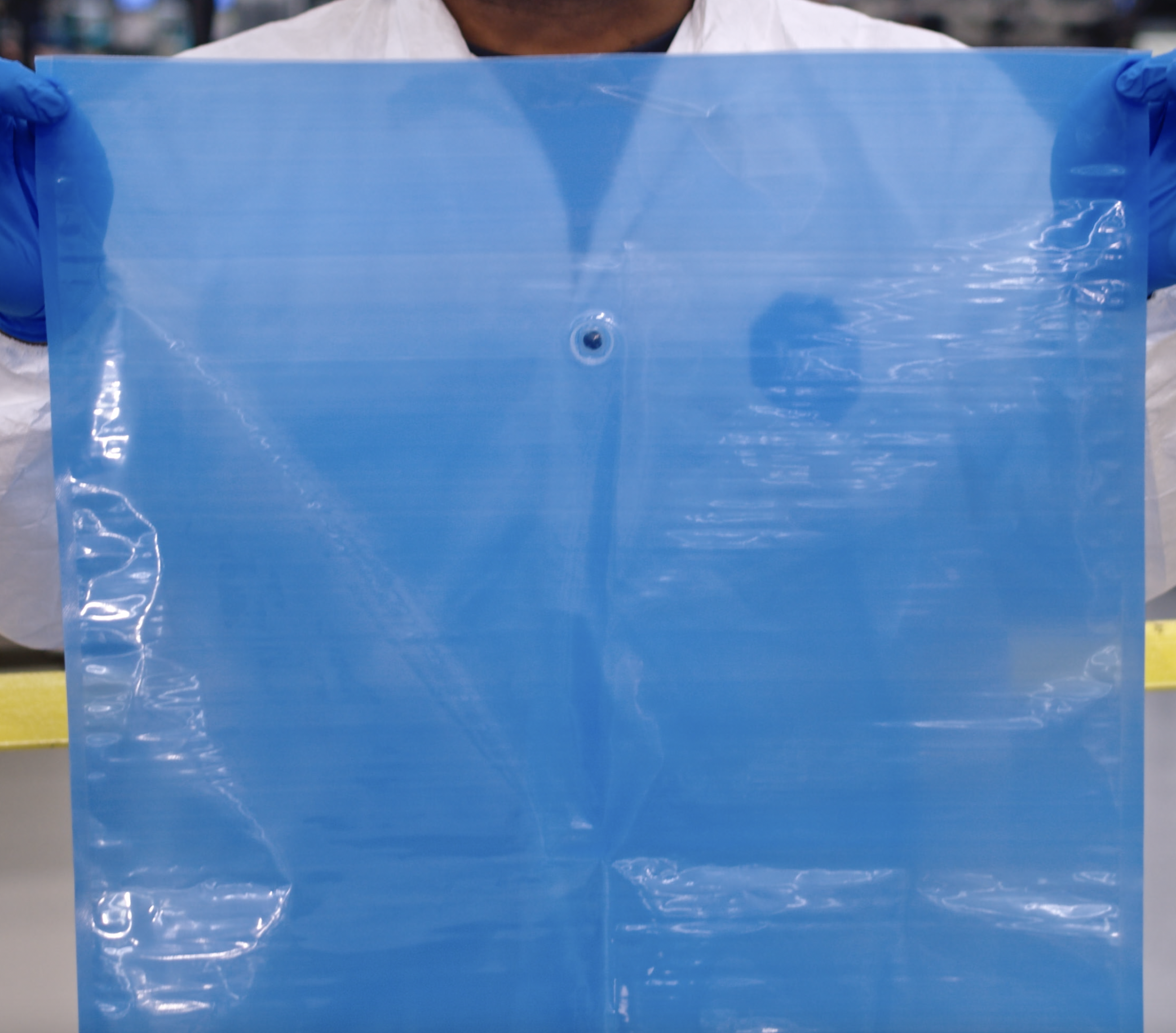

Secondary food packaging is used for both ease of inventory and additional protection during transport. For example, a company that sells pre-portioned bags of chicken nuggets to a restaurant may use a larger secondary bag to group multiple pre-portioned bags for easy inventory tracking. We would work with the food supplier to manufacture a secondary bag that meets specifications for cleanliness and puncture resistance during transport, along with any other necessary barrier qualities like aroma control.

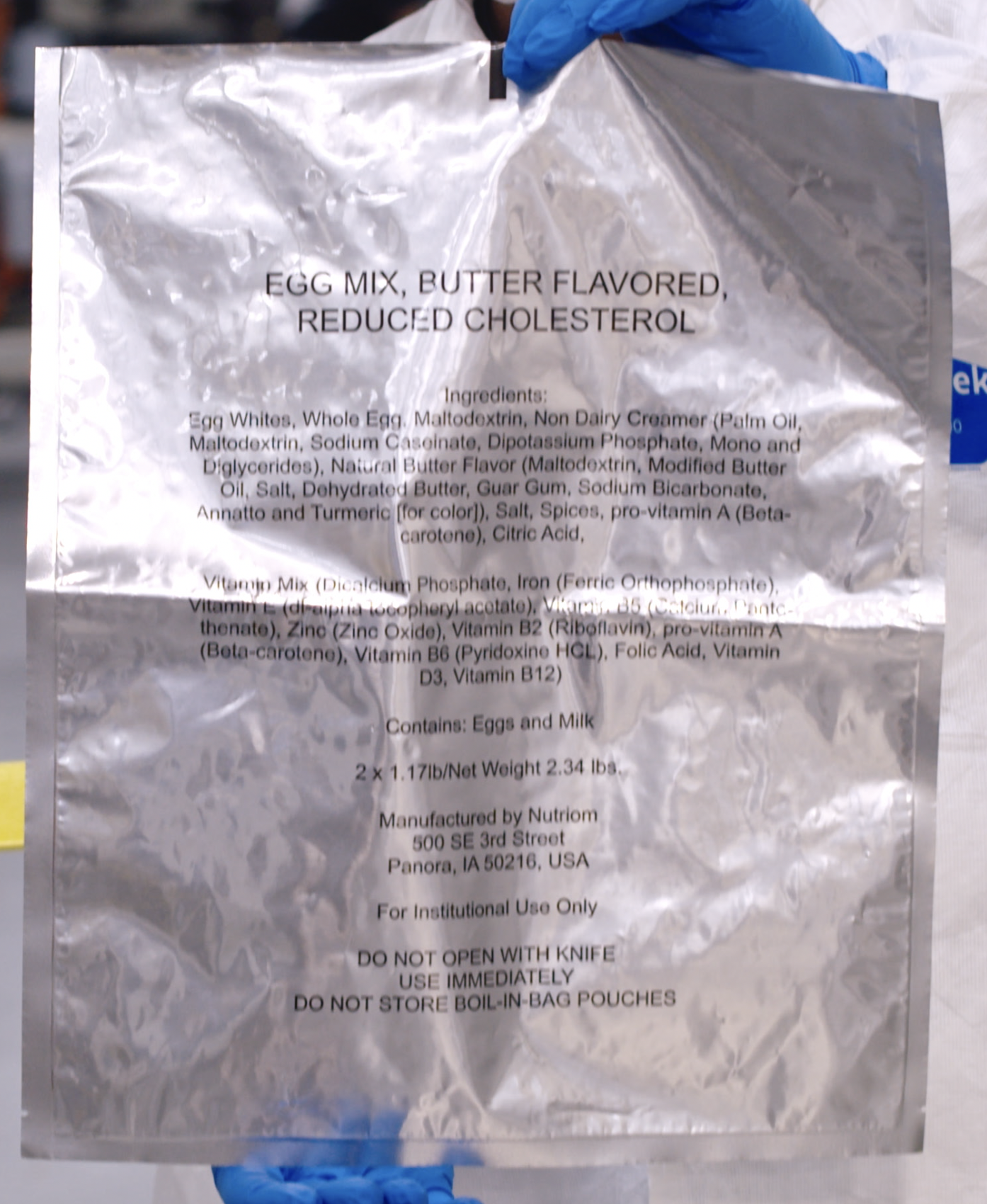

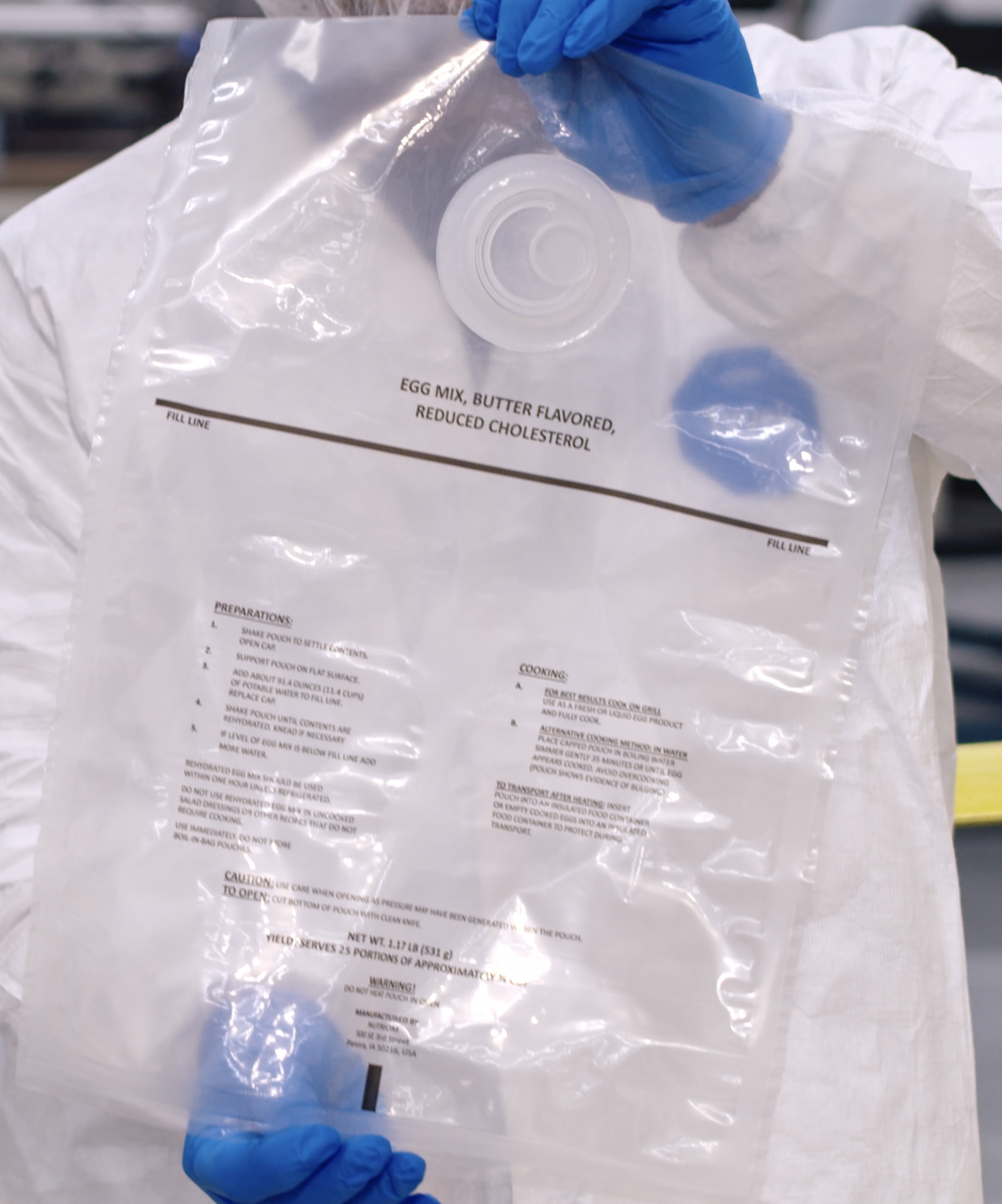

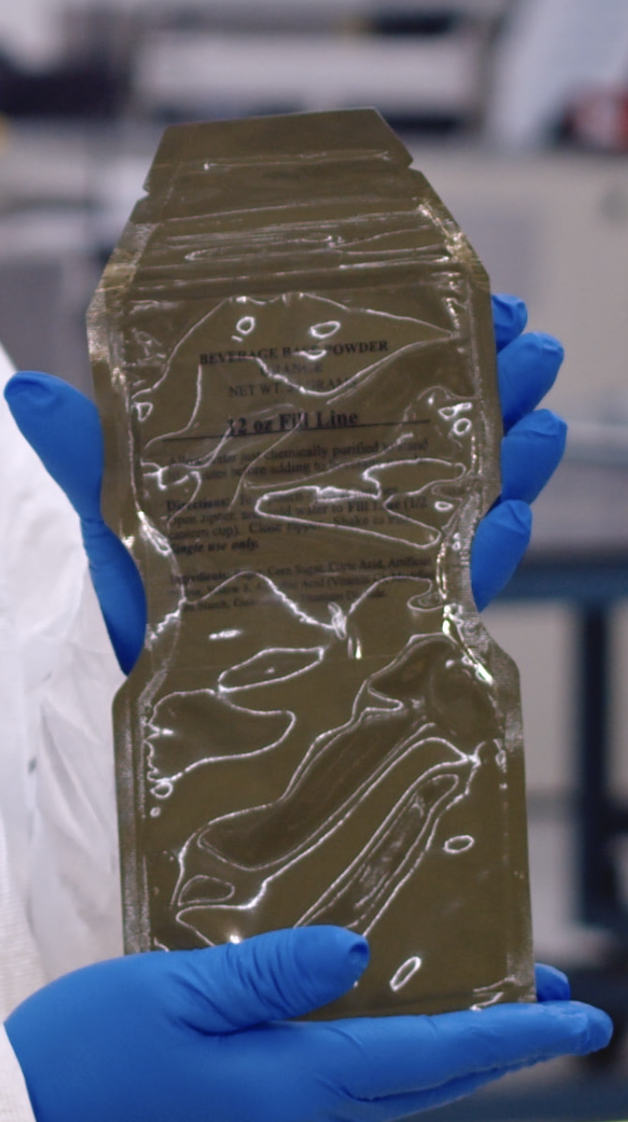

Institutional food packaging is used to package bulk food that is not intended for retail sale. This type of packaging is frequently seen in cafeterias, commissaries, food courts, bakeries, and commercial kitchens. For example, we can produce bags with fitments for rehydrating freeze-dried egg products, and handled bags for delivering freshly made soups for redistribution.

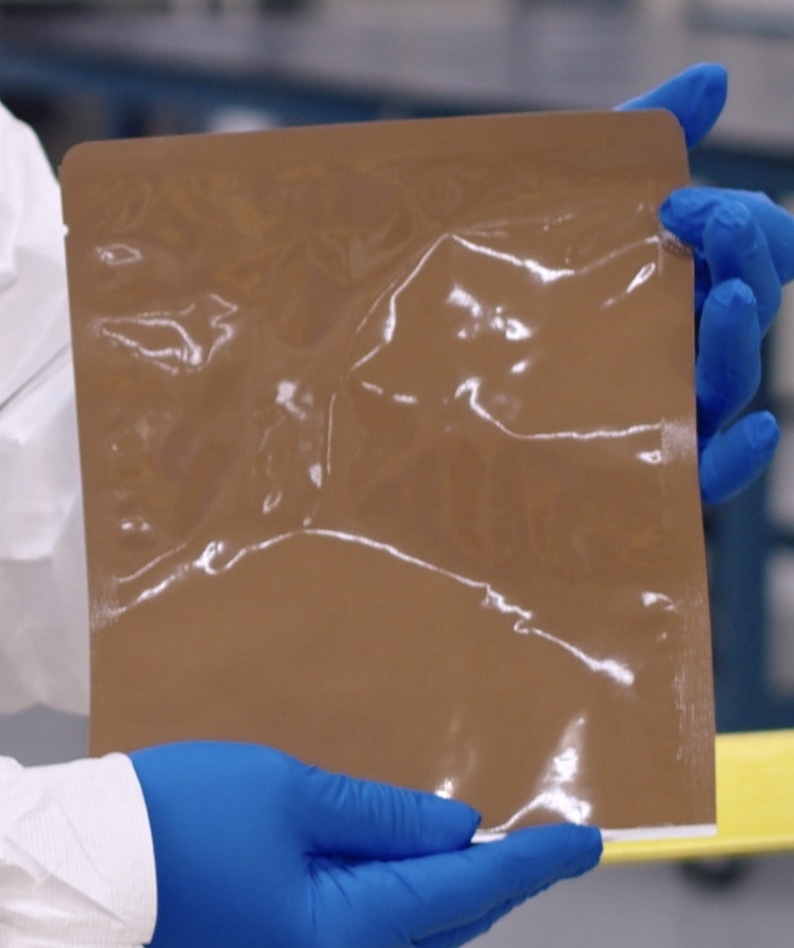

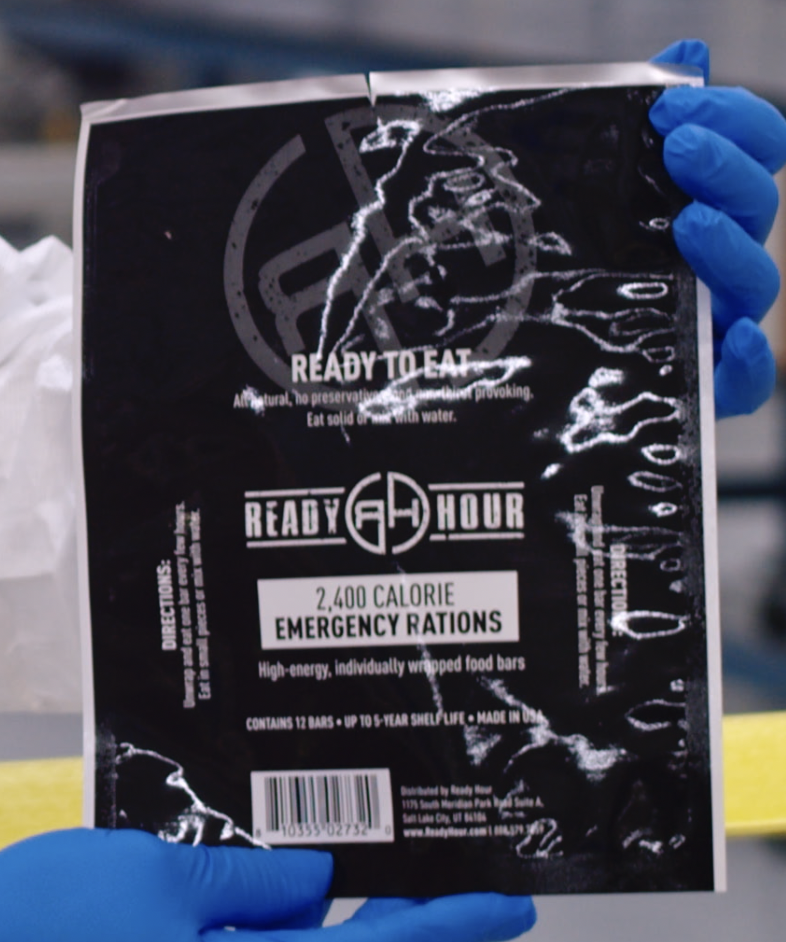

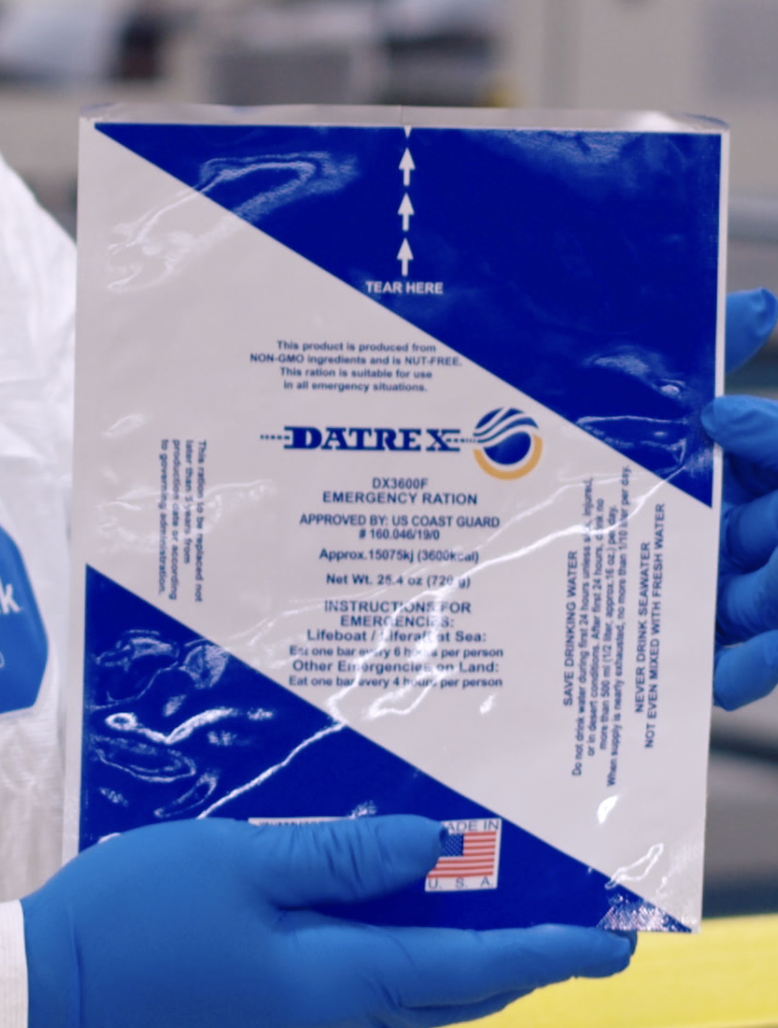

Government Rations Programs are used by the military to keep food stable and appetizing when reheated, flexible packaging for government rations programs helps safely deliver food to our troops. Businesses that supply their food to the DLA for rations programs have rigorous requirements, and we have the capabilities and knowledge to ensure that all packaging specifications are met.

How to Shop for Food Packaging

While many online retailers can offer pre-made pouches suitable for novelty use, organizations and businesses with established food products often build relationships with a flexible packaging convertor or even a co-packer who works with a convertor in order to ensure all specifications and regulatory requirements are met and to make sure the end product is safe for consumption.

At Heritage Packaging, we work directly with brand owners, food service providers, grocery stores, and their co-packers to engineer the perfect packaging solutions for food products. Next, we’ll look at the importance of choosing an SQF-certified packaging supplier.

Making Sure Your Food Packaging Supplier is SQF Certified

If you’re shopping for food packaging, your supplier likely needs to be SQF-certified to ensure the highest food safety standards are met- Your state laws may even require it. Per the SQF Institute, SQF stands for Safe Quality Food. It is a rigorous food safety and quality program that helps food producers assure their buyers that their food products meet the highest possible global food safety standards. The codes are designed to meet industry, customer, and regulatory requirements for all sectors of the food supply chain.

Heritage Packaging is certified in SQF Food Safety Code for Food Packaging, Edition 9. We have both a Quality and Food Safety Management System that lead us through the production of safe, consistent, high-quality products that meet or exceed our customer’s expectations. This includes comprehensive standard operating procedures and associated forms, following Good Manufacturing Practices and maintaining a clean facility, qualifying raw material vendors, operating a documented preventative maintenance program, and following strict sanitization procedures.

This stringent program is not easy to pass, and customers can feel assured knowing that their SQF-certified supplier can produce quality products; however, it’s in the customer’s best interest to do their due diligence and get to know their supplier.

What does their facility look like? Is it well-maintained year-round and not just when an audit is coming up? Keeping in mind that some processes and information may be proprietary and confidential, it is still important to have an open line of communication with your packaging supplier.

At Heritage Packaging, we welcome our customers to schedule a tour of our plant and get to know the people behind the product!

Custom Products for the Food Industry

Next, we’ll take a look at the custom products and process that we offer at Heritage Packaging. Most frequently, we produce bags, pouches, and liners in a variety of configurations and special features for the food industry.

Pouches and Bags

We engineer and manufacture:

Shaped bags and pouches

Hot fill pouches

Retort pouches

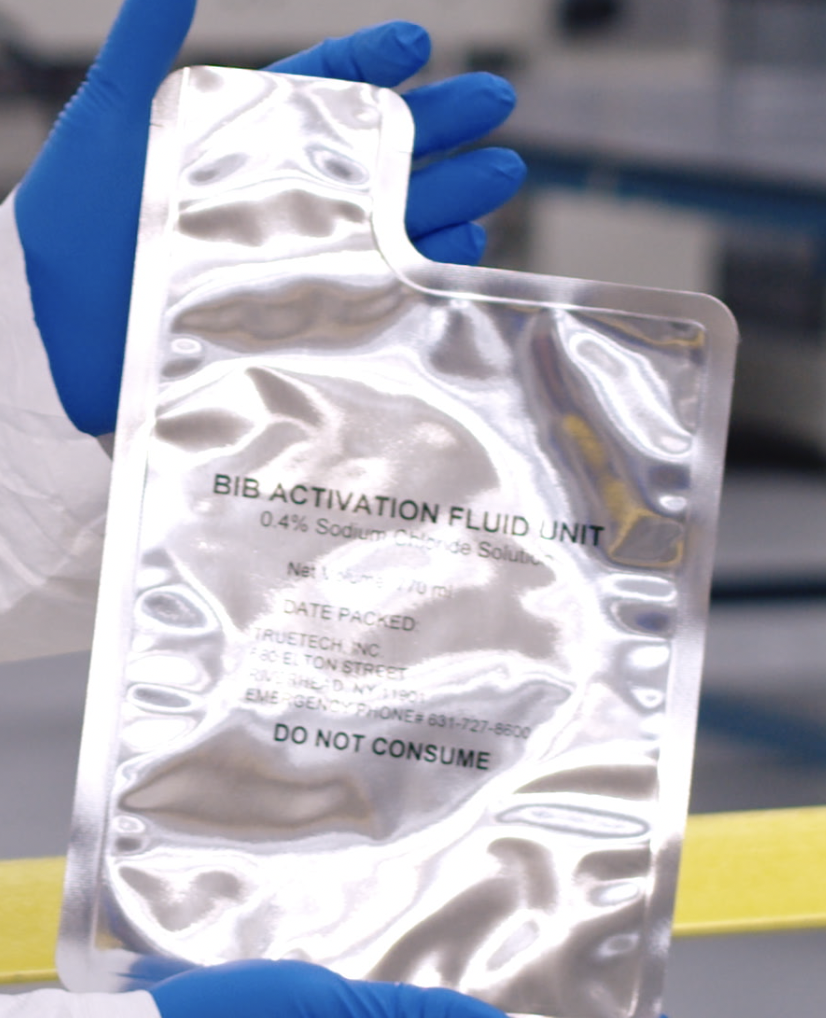

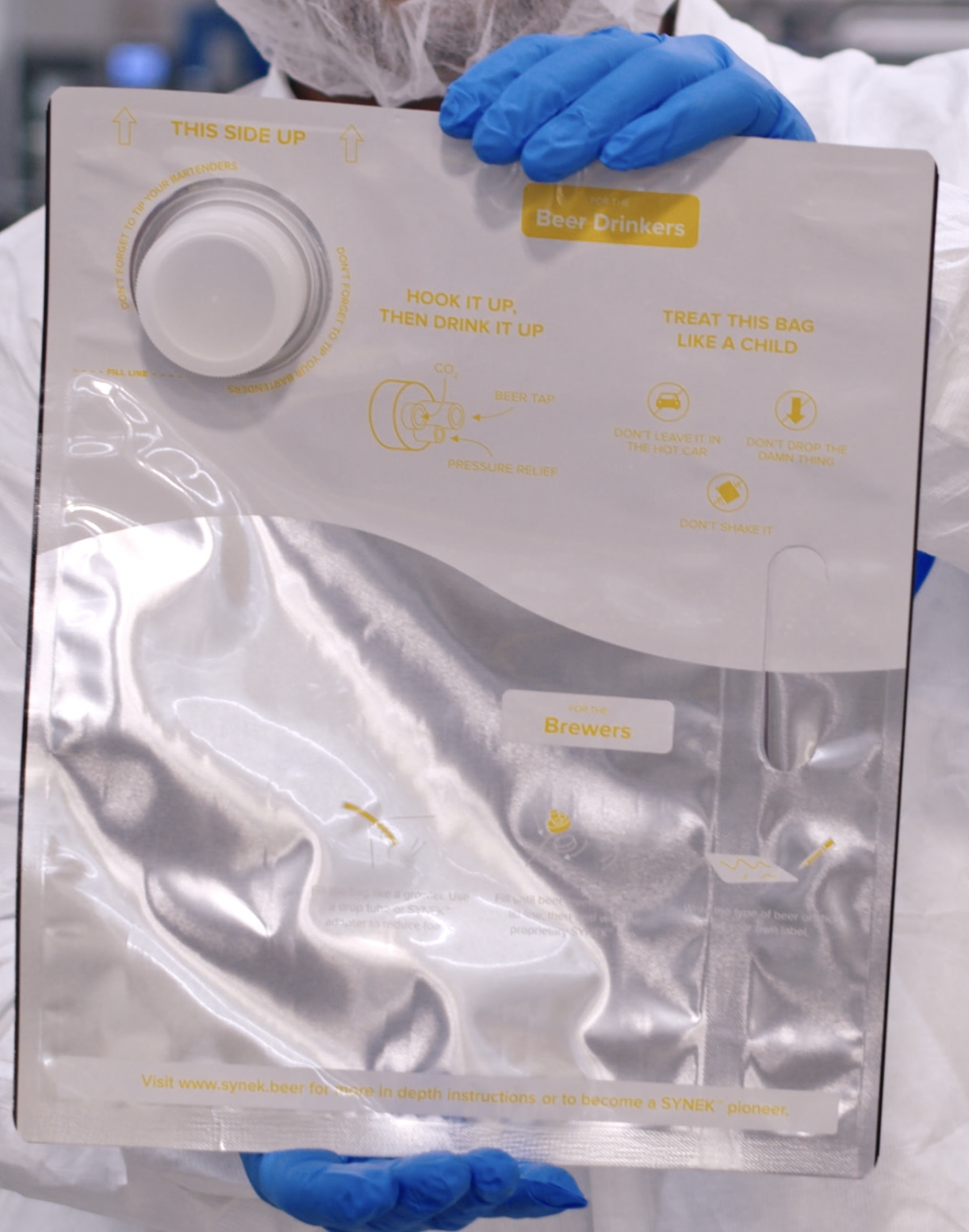

Boil-in-Bags (B-I-B) with or without fitments

Zipper Closure bags

And more!

A large variety of special features and secondary operations are available, including the installation of molded fitments and spouts, handle holes, and the use of heavy-duty barrier materials.

Liners

We engineer and manufacture

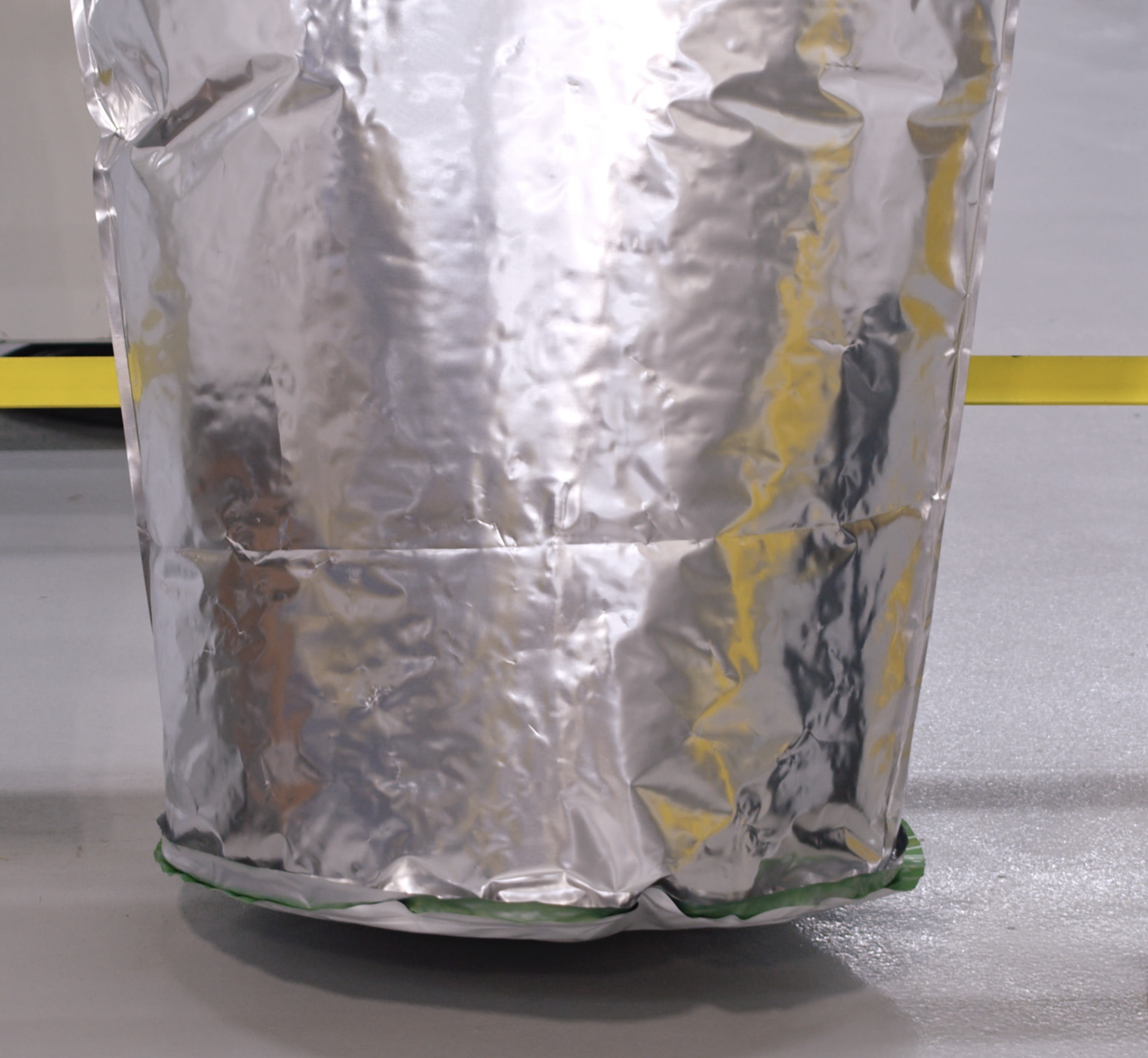

Round bottom barrier liners

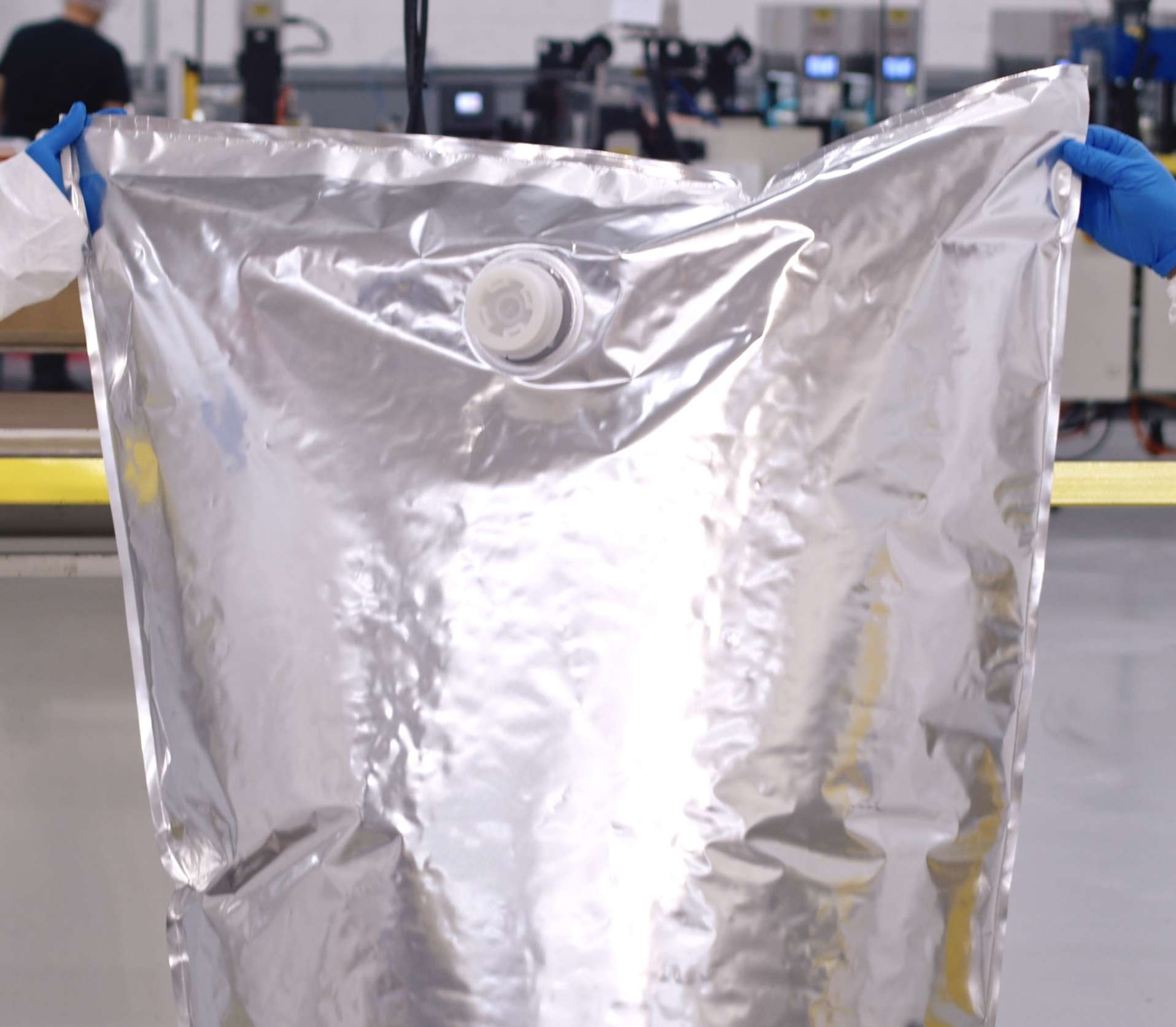

Bag-in-Box (BiB) liners

Pillow-style bulk liquid liners

Form fit container liners for dry flowables with fill and discharge options

And more!

Similar to bags and pouches, we offer many special features and secondary operations to our liners, including performance-enhancing additives like EVA, EVOH, or Metallocene catalyst, the use of heavy-duty barrier materials or FDA-grade mono-layer and co-ex films, as well as molded fitment installation.

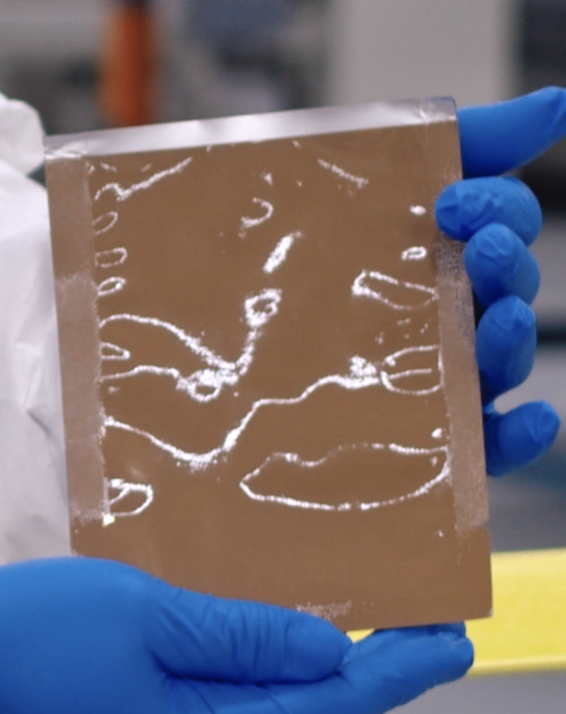

Our Custom Process

Sometimes a packaging solution is highly specialized but simple, and we can turn around a quote within 1-2 business days. More complicated projects require the expertise of our engineering team, who work with you to design an option that will provide the best fit & the best barrier properties to protect or preserve your product. Oftentimes all we need is a deeper conversation to move the process along, but this stage can also include technical drawings, producing prototypes, and performing multiple quality tests to make sure your specifications are met.

At Heritage Packaging, we adapt our processes to meet our customers where they are. We are staffed to handle low-volume short-term commitments with a production run of 5,000 to 100,000 pieces, as well as long-term high-volume programs. We regularly produce finite intermittent orders from numerous different customers, while at the same time producing well-established product lines on a continuous basis through collaboration with the brand owners.

Whether your needs are short-term or long-term, we can help get to a perfect packaging solution as quickly as possible when we know the details of your application, like:

Is the packaging product meant to be used as an eating utensil in addition to simply housing the food? For example, a pouch that contains powdered protein gets water added to it, is shaken, and then is used to drink by the consumer.

What is the filling process, and how should we configure your shipment for the filler? For example, should pouches with molded fitments be bulk packed in poly-lined cartons or mounted into filler feed rails?

Is this for a primary or secondary packaging application?

What temperature is the product filled at?

What are the seal strength requirements?

And many other details that our packaging professionals are equipped to talk you through.

Conclusion

Type “flexible packaging for food” into Google and you can quickly find yourself down a rabbit hole of options, with many top searches for custom-printed pouches from converters that may not be SQF-certified. We hope this guide helped you understand the multiple different uses for food packaging, and gave some insight into what you need to consider before purchasing your own packaging product.

If a custom packaging solution sounds right for your food product, send us an email or give us a call and our sales team will help collect the information needed to come up with your perfect packaging product. And If you want to know more about what we do at Heritage Packaging, be sure to sign up for our newsletter in our footer, and view our other blog articles for more free resources and answers to frequently asked questions.