Bags and Pouches

Flexible pouches and barrier bags are used across many industries because they can cost less to produce than rigid alternatives, can reduce transport space and cost; and are a practical and popular choice for consumer use.

Whether you need a pouch to keep food stable on the grocery store shelf or a barrier bag that will help protect vaccines in transit, we are equipped to manufacture highly specialized packaging solutions that ensure product integrity.

Our facility is certified in SQF Food Safety Code for Food Packaging, Edition 9.

Made-to-Order

You pick the configuration, closure method, material, quantity, and any special features; or have one of our packaging experts guide you to the best solution. Use the examples below as a starting point, and get in touch to begin an order.

Choose a Configuration

Flat Bag

Choose 2 or 3 seals.

Stand-Up Pouch

Can be rectangular or contour-shaped.

Contour-Shaped Pouch

Can be flat or 3-D. Many shapes are possible!

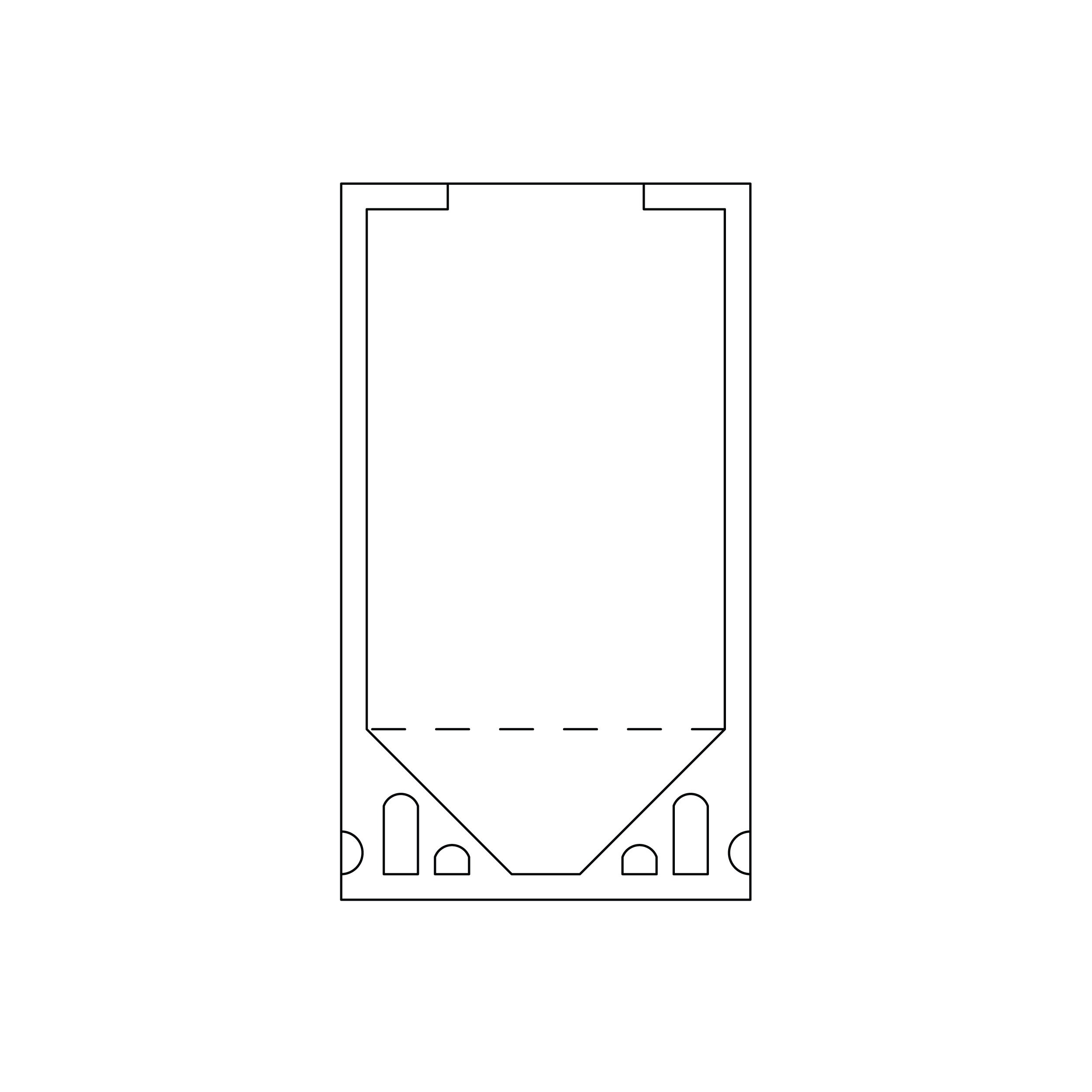

Flat Bottom Bag

Side Gusset Bag

Specify Your Requirements

Materials

Choosing the proper material for your application is our specialty, and is a critical aspect of protective packaging. We use a wide array of flexible materials, barrier materials, Mil-Spec materials, custom processed material, and even proprietary material to manufacture your perfect packaging product.

Closure Methods

Bags and pouches are typically finished with zippers, Velcro®, or molded fitments; or include a heat-sealable opening. Choosing the right closure depends on the level of barrier protection required, how frequently the items will be accessed, how the end-user will handle the product, and more.

Optional Features & Secondary Operations

Our equipment and processes allow us to offer a variety of inline and secondary operations like fitment and valve installation, die-cutting, grommeting, imprinting, cleaning, kitting and more. We help customers find the perfect features during the design phase of an order, and once we know the details of the application.

Competitive Pricing

While there is no minimum piece requirement, we offer the best value on machine-run pouches and bags to customers who need as few as 2,500 pieces up to a million and beyond.

We offer prototyping and trial runs with hand fabrication pricing for customers who aren’t ready to commit to a full production run.

Fitment Installation

Installing molded fitments into pouches is our specialty. Our capabilities include perimeter installation of boat-shaped fitments and flanged fitments or glands installed in the face of bags, liners, and pouches.

We provide fitment installation on pouches made by Heritage Packaging, or on premade products that you send to us.

Unique Applications

Need tubing heat-sealed into perimeter seals of pouches, die-cut handles applied in-line, or have a unique specification that you’re struggling with?

Our team loves a challenge! Talk to our packaging experts for complex solutions to your high-risk applications.