Box & Carton Liners

Box and carton liners are used to line the inside of intermediate-sized rigid cartons, protecting the goods inside from contamination or providing a barrier to permeation, depending on the application and the desired level of barrier protection. They are a good fit for a wide variety of products like automotive parts, metal bearings, or food items like soup stock, sauces, dressings, and more.

Our facility is certified in SQF Food Safety Code for Food Packaging, Edition 9.

Made-to-Order

You pick the size, configuration, material, ply construction, and any special features; or have one of our packaging experts guide you to the best solution.

Use the examples below as a starting point, then get in touch to begin an order.

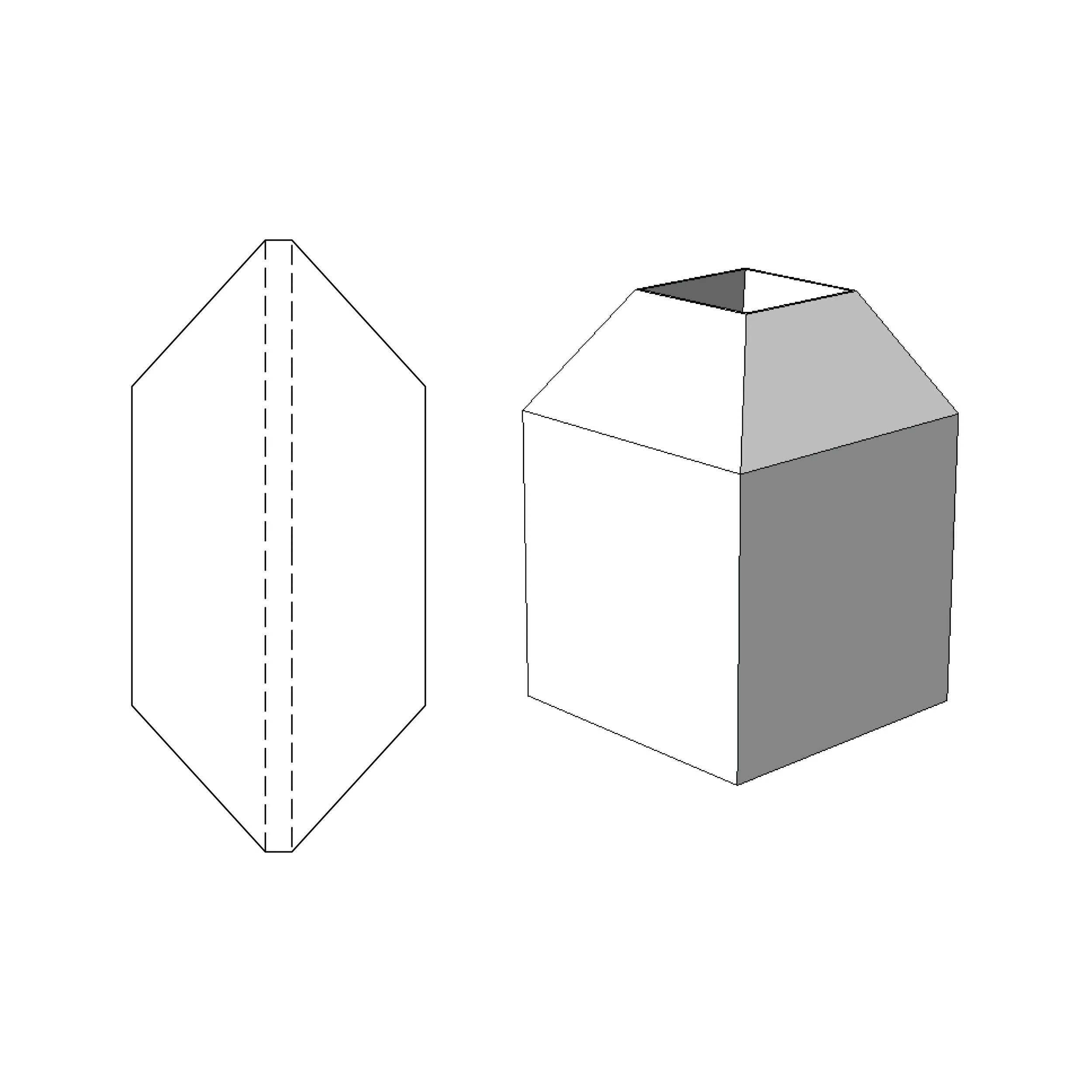

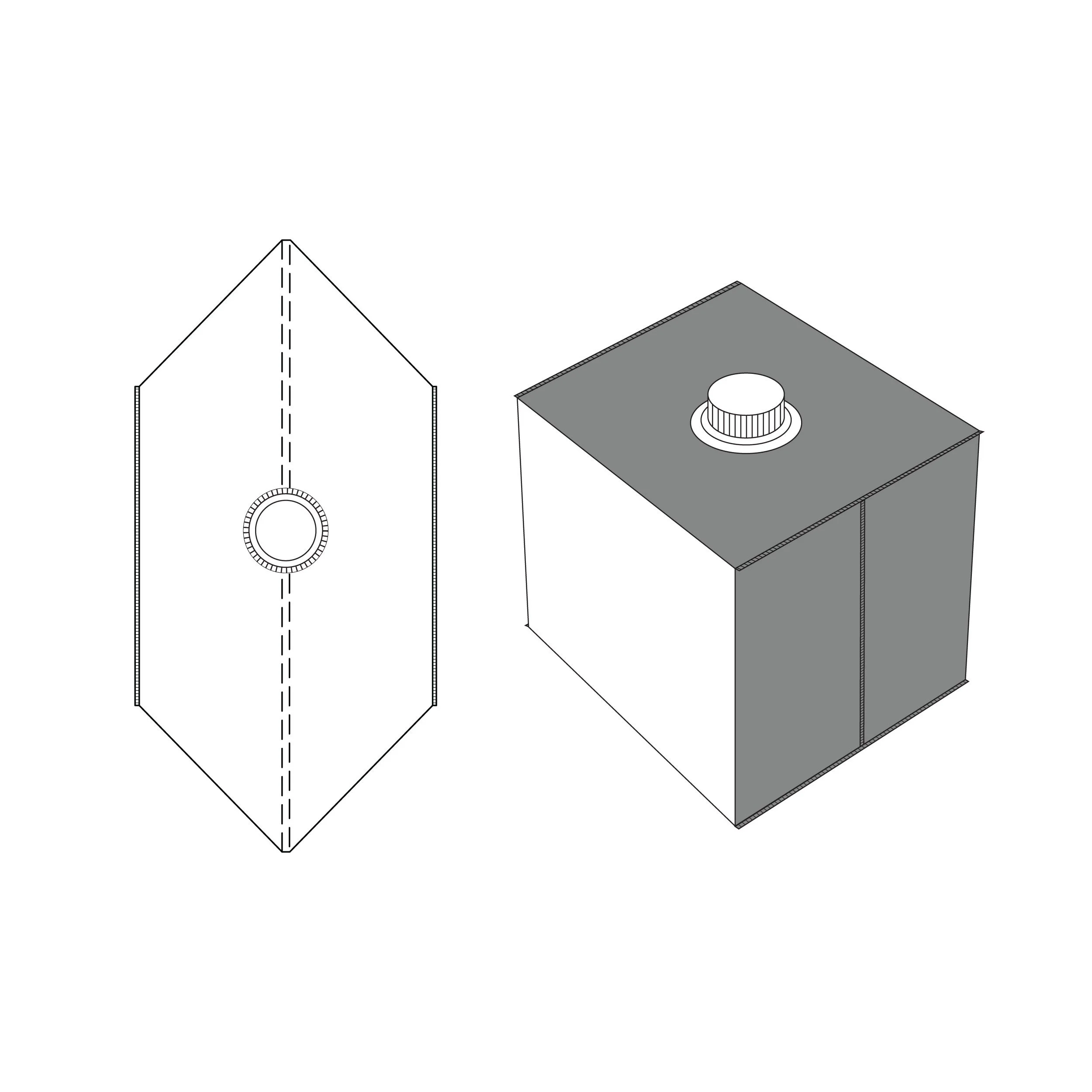

Choose a Configuration

Flat Bottom, Open Top

Flat Bottom, Tapered Top

Side Gusset, Open Top

Flat Bottom w/ Fill Spout Top

Specify Your Requirements

Materials

Our liners are produced from multi-layered laminations that provide high levels of barrier protection against the permeation of unwanted elements as well as co-extruded and/or monolayer blown films. The barrier structures of these laminations consist of materials like foil, metalized polyester, EVOH, Nylon, and custom blended sealant layers that provide superior heat seal strength.

Materials are selected based on the level of barrier protection required for your application. Too much or too little protection can affect your packaging’s success.

Closure Methods

Liners for applications requiring minimal barrier can be closed with tie wraps, tape, rubber bands, etc. High barrier applications require either a fitment with a screw cap or heat seal closure.

Optional Features & Secondary Operations

We offer a variety of inline and secondary operations like fitment and valve installation, labeling, and more depending on your application.

Optional gamma irradiation (25-45KGy) ensures sterilization that is both safe and cost-effective.

Ready-to-Use

Liners keep your product uncontaminated and ready for immediate use upon opening. Our barrier materials provide a controlled internal environment that prevents product degradation caused by the permeation of water vapor and oxygen into the interior.

Cost-Effective

Our liners provide a controlled internal environment and eliminate the need for expensive climate-controlled storage space. Let us recommend the appropriate level of barrier properties needed to prevent the permeation of unwanted gases and elements.

Efficient

We can customize liner configurations to your filling equipment with integral fill spouts or fitments and glands, and other special features to ensure efficient filling and discharging processes.