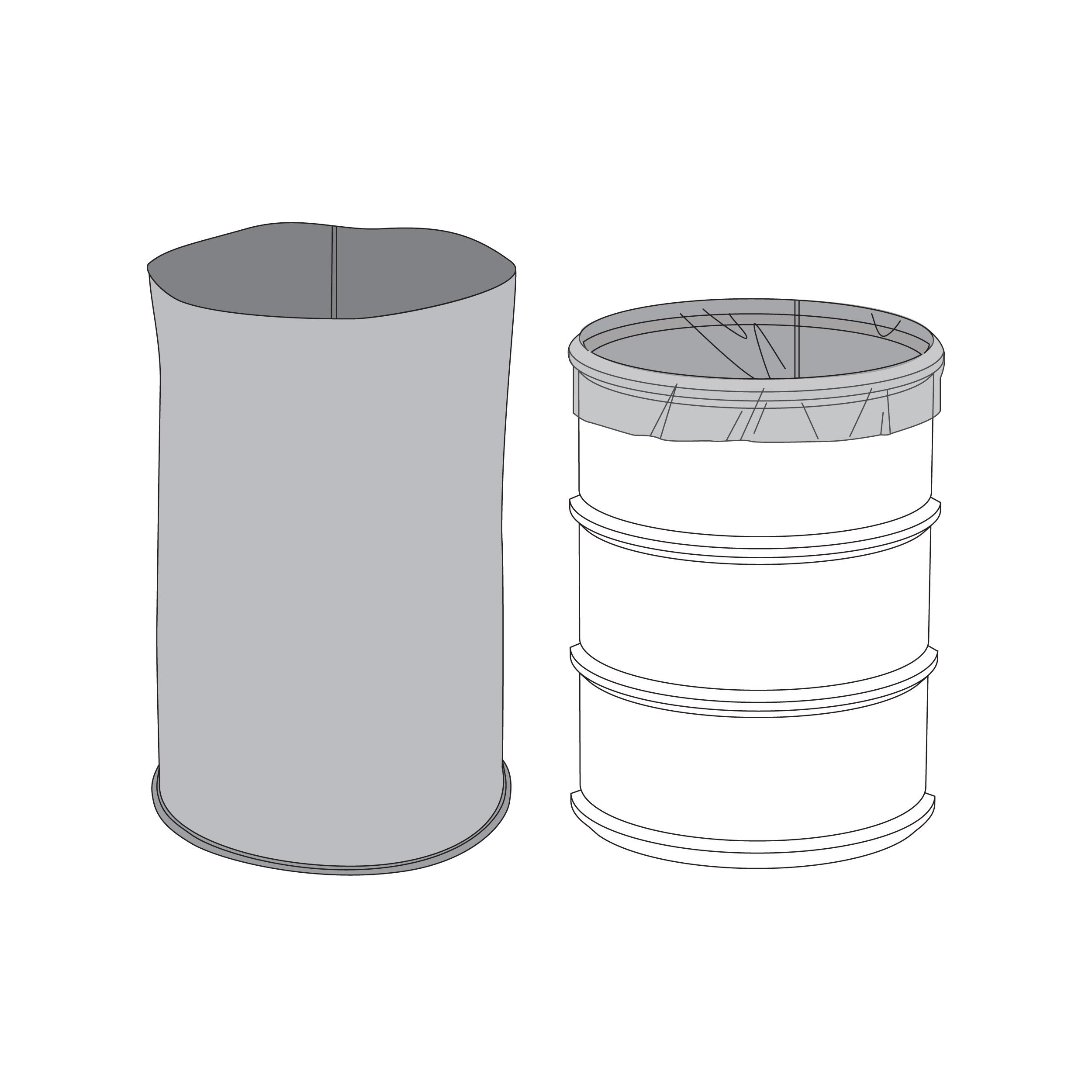

Round Bottom Barrier Liners

Round bottom barrier liners are made to fit snuggly in cylindrical containers. They offer a high barrier to permeation which makes them suitable for the storage and transport of critical goods like food items, medicinal powders, pharmaceuticals, adhesives, and more.

Our facility is certified in SQF Food Safety Code for Food Packaging, Edition 9.

Made-to-Order

You pick the size, material, ply construction, and any special features; or have one of our packaging experts guide you to the best solution.

Use the examples below as a starting point, then get in touch to begin an order.

Choose a Configuration

Round Bottom, Open Top

Round Bottom with Heat-Sealed Top and Molded Fitment

Specify Your Requirements

Materials

Our round bottom liners are produced from multi-layered laminations that provide high levels of barrier protection against the permeation of unwanted elements. The barrier structures of these laminations consist of materials like foil, metalized polyester, EVOH, Nylon, and custom blended sealant layers that provide superior heat seal strength.

Laminations are selected based on the level of barrier protection required for your application. Too much or too little protection can affect your packaging’s success.

Closure Methods

Round bottom liners without fitments are shipped with an opening that should be closed via a heat sealing operation. Some customers opt to have molded fitments installed in a sidewall that include screw cap closures and a heat-sealed top.

Optional Features & Secondary Operations

We offer a variety of inline and secondary operations like fitment and valve installation, and tape and tear notch installation. Optional gamma irradiation (25-45KGy) ensures sterilization that is both safe and cost-effective.

Ready-to-Use

Our round bottom design allows for maximum evacuation of full volume so there is no wasted container space, and product doesn’t get trapped because there are no gusset folds.

Efficient

If you’re considering purchasing new drums and equipment because they are no longer suitable for your product or easily cleaned, consider a liner instead. Adding a liner allows businesses to keep their machinery, handling equipment, and storage racks that are already in use.

Cost-Effective

Avoid the high cost of rigid containers that require cleaning and or revalidation after use. Use a round bottom liner to provide sanitary storage and transport of products in standard, inexpensive drums, totes, and other rigid containers instead.