Covers, Shrouds, and Crate Liners

Reduce installation time and potential error with flexible covers that don’t require onsite fabrication by your employees. Choose from simple 3-D configurations for flat or slanted surfaces, or glove-fit covers in nearly any size and shape. All covers, shrouds, and crate liners feature hermetic heat seals. Covers that utilize a base sheet are suitable for vacuum sealing, creating a fully enclosed environment.

Made-to-Order

You pick the configuration, closure method, material, and any special features; or have one of our packaging experts guide you to the best solution. Use the examples below as a starting point, and get in touch to begin an order.

Choose a Configuration

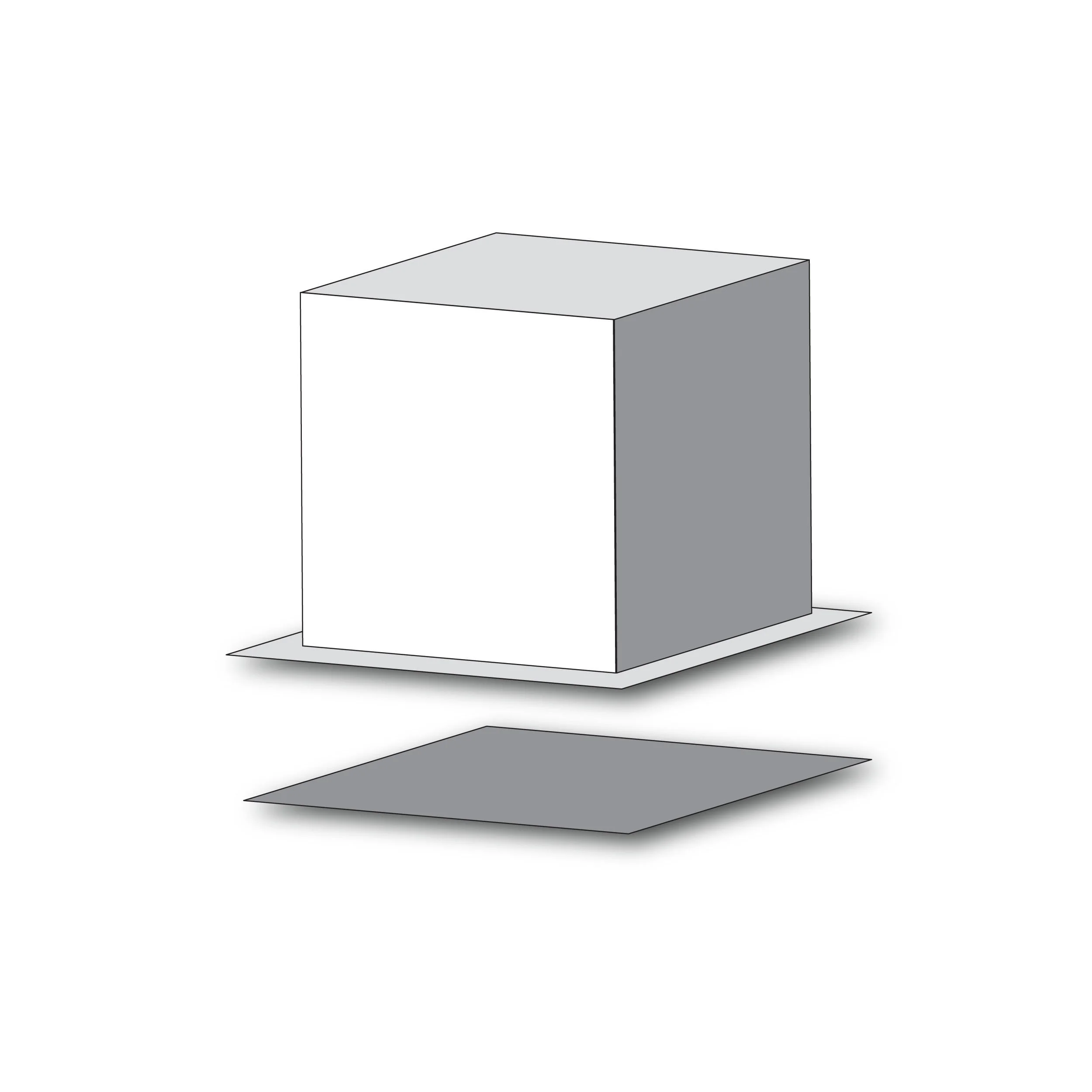

3-D Cover or Shroud

Used to protect items like pallet loads, machinery, and other instruments from dust and contamination. Not an airtight enclosure.

3-D Cover with Flat Base Sheet

A fully enveloped enclosure that can be adhered or heat-sealed closed.

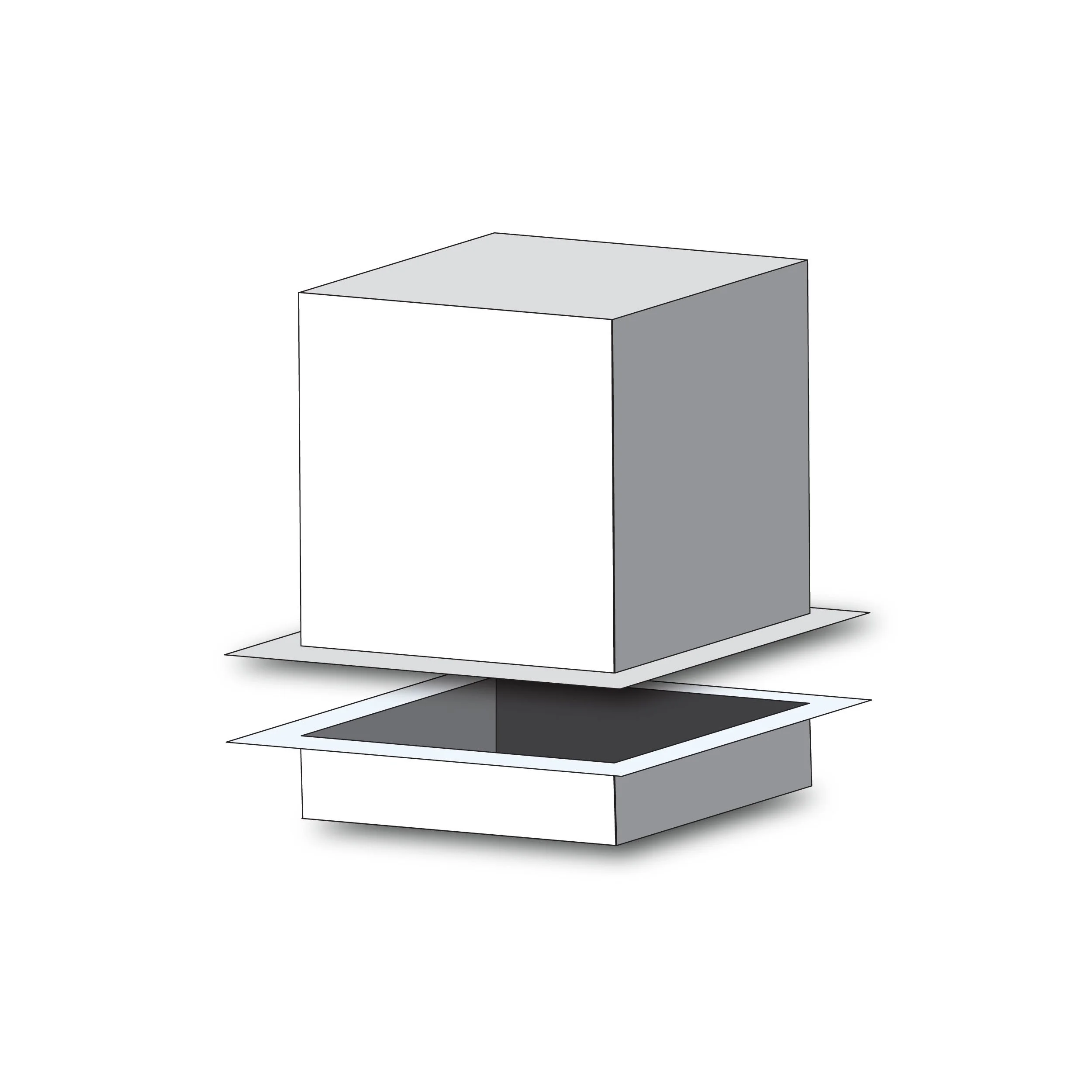

Flanged 3-D Cover with Flat Base Sheet

A fully enveloped enclosure with an easy-to-seal flange.

Flanged 3-D Cover with Flanged Tray

Exclusive to Heritage Packaging, our flanged cover systems make it easy to heat-seal top and bottom covers by providing a flat surface that a manual heat sealer can easily access.

Cylindrical Cover or Shroud

Featuring a round top with a cylindrical body. Perfect for items like vertical air compressors, metal valve castings, or even personal saunas.

Glove Fit Covers & Crate Liners

Ideal for items that are irregularly shaped, we can engineer a cover system that fits snuggly to the shape of anything from an airplane to wind energy gears.

Drawing above shows two flanged cover halves slid over a shaft from opposite ends, with one half contoured to the shape of the tapered shaft.

Specify Your Requirements

Materials

Choosing the proper material for your application is our specialty, and is a critical aspect of protective packaging. We use a wide array of flexible materials, barrier materials, Mil-Spec materials, custom processed materials, and even proprietary materials to manufacture your perfect packaging product.

Closure Methods

Covers without a base sheet or tray are typically left open on one side. Covers that include base sheets or bottom trays are closed by heat-sealing the material or flanges together, or by using a zipper, Velcro®, or various adhesives. Choosing the right closure depends on the level of barrier protection required, how frequently the items will be accessed, how the end-user will handle the product, and more.

Optional Features & Secondary Operations

Our equipment and processes allow us to offer a variety of additional features to covers like viewports or windows, VCI emitters and desiccant inclusion, vacuum valves, pressure relief valves, humidity indicators, tip-n-tell, lifting loops, grommets, document pouches, and more. We help customers find the perfect features during the design phase of an order, once we know the details of the application.

Save Time & Money

Use premade covers instead of onsite fabrications to save time and money! We work with customers to fully understand how their products are handled during packaging so their professionally-made covers arrive ready and easy to use, without the need for costly trial and error associated with DIY methods.

Get Consistent Heat Seals

Our factory-made heat seals are done at consistently controlled parameters for heat, time, and pressure, and assure fewer failed seals than manual onsite methods.

The Perfect Package

Sending your product to a customer? Consider packaging that’s clean, crisp, and made for protection. Engineered, factory-produced covers create a more finished look with a higher perceived value than covers fabricated onsite and by hand.