How It’s Made: Flexible Packaging for Block Cheese

Why Flexible Packaging Plays a Major Role in Getting Aged Cheeses to Your Fridge

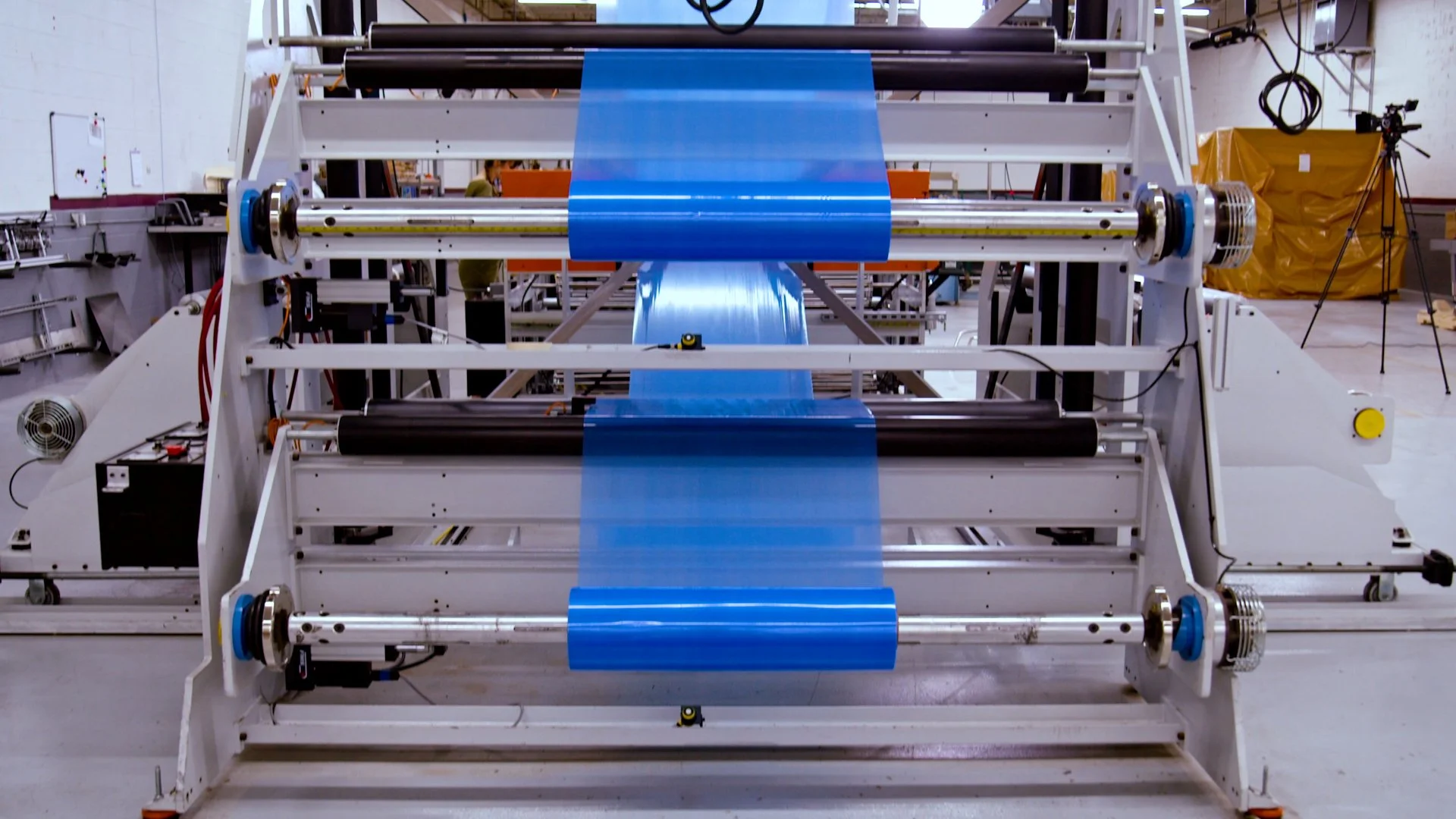

Heritage Packaging can create a wide variety of products, and one unique capability is creating flat bags with degassing valves for block cheese. The video below is a walk-through of the manufacturing process on one of our pouch and liner machines. Hear first-hand from our Sales & Engineering Manager along with one of our packaging experts about how this impressive machine creates specialty flexible packaging for a critical need in the food industry.

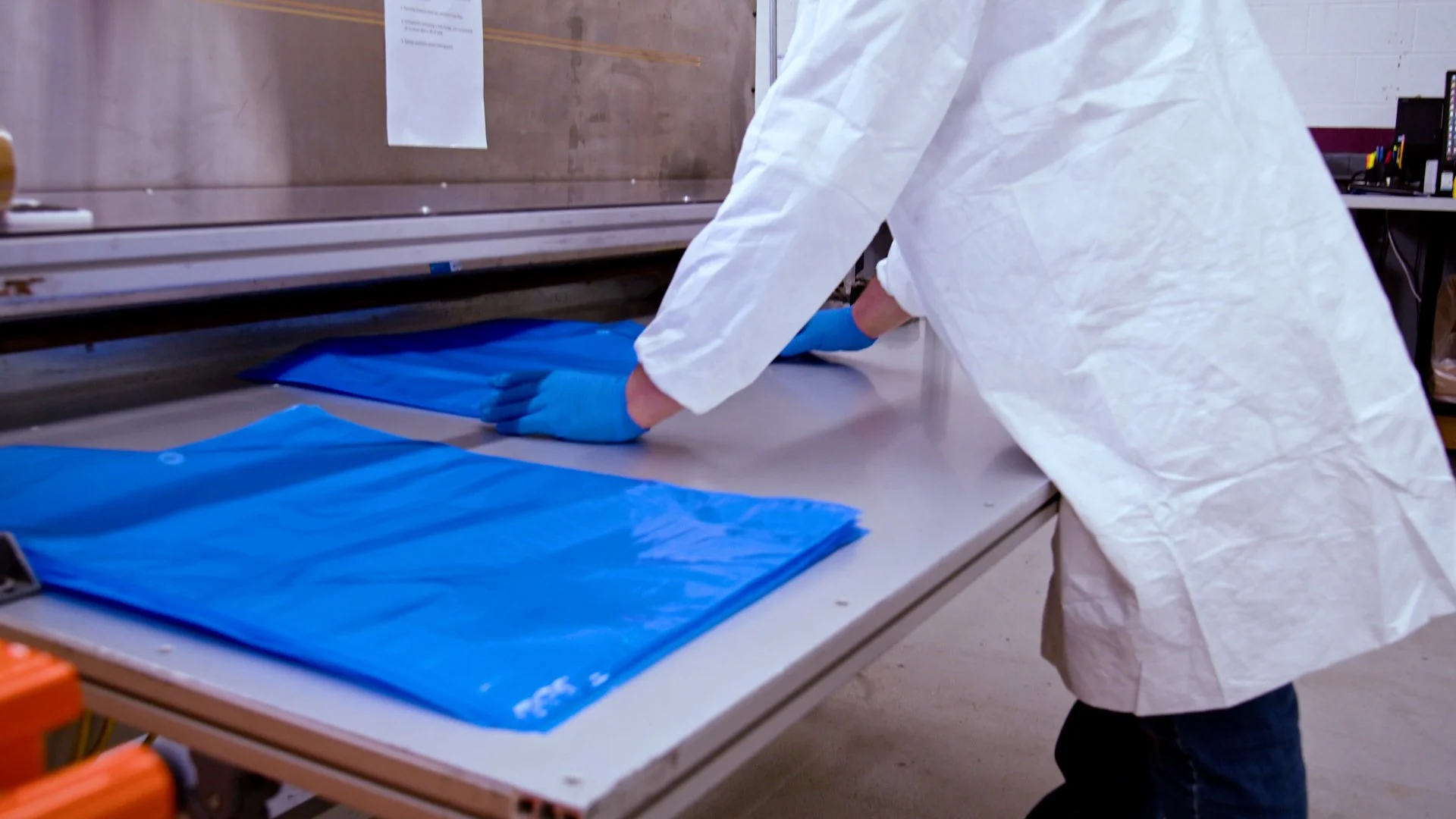

Immediately, you can see this is not the packaging for cheese seen on store shelves. Cheese manufacturers use these flat bags to package block cheese (we’re talking HUGE) while it ages, preventing mold growth. Once the cheese is properly aged, it’s processed for retail sale. The degassing valves are a critical part of ensuring the cheese that makes it to market is safe for consumption. Let’s walk through the features and process.

What is the Product?

A 3-seal flat bag with degassing valve made from co-extruded barrier film

Used by cheese manufacturers to package block cheese while preventing the growth of mold

After the cheese is properly aged it is then reprocessed for retail sale

What is a Co-Extruded Barrier Film?

Co-extruded films are made with two or more materials being extruded simultaneously into a tubular configuration

A barrier film that prevents the permeation of oxygen and moisture vapor

Oxygen and moisture vapor can promote mold growth which would result in the loss of product

What Does the Degassing Valve Do?

It keeps the bag from inflating due to the outgassing from the cheese, and with the bag film vacuumed tight against the cheese block it is much easier for automated vacuum cups to pick up the blocks and move them.

What’s unique about our process is that valve installation happens inline, which means the same machine that produces the bag installs the valve. It’s less expensive than a manual secondary operation and ensures that the valve is in the same location on each bag.

What Machine is This Done On?

This machine produces pouches, bags, and liners

It can use 1 to 4 webs of barrier material at one time

What Else Can This Machine Do?

Literally hundreds of different products!

It can be used in food packaging, medical packaging, for dry flowables, and even for military or aerospace use.

This machine can make:

2-seal folded-bottom flat bags

3-seal flat bags

3-web large bottom-gusset bags

4-web large side gusset liners from barrier materials, (with & without integral fill and discharge spouts), that are used to line FIBC’s and Gaylord containers and minimize oxygen and moisture vapor permeation

Wide multi-web Roll stock

There is even more information packed into the video on how the machine operates, but that’s definitely more fun to watch than it is to read about. If you haven’t already, check out the video above.

Conclusion

We are proud to have this machine in our arsenal and to be able to create unique packaging solutions that solve unique challenges. In this case, we were excited to trial a product that is integral in the production of one of our favorite things in the world: cheese!

If you want to keep learning, be sure to sign up for our newsletter to have our content delivered straight to your inbox.

Need to talk to our team about your specific challenges? Send us an email, fill out our quote form, or give us a call to see if an engineered flexible packaging solution is right for you.

P.S. We’re going to be having some fun on social media in the coming weeks and releasing some of our employees’ favorite cheeses. If you love cheese and want some ideas, be sure to follow us on Facebook!