Are Your Heat Seals Hermetic?

And Do They Need To Be?

Heat Sealable Materials

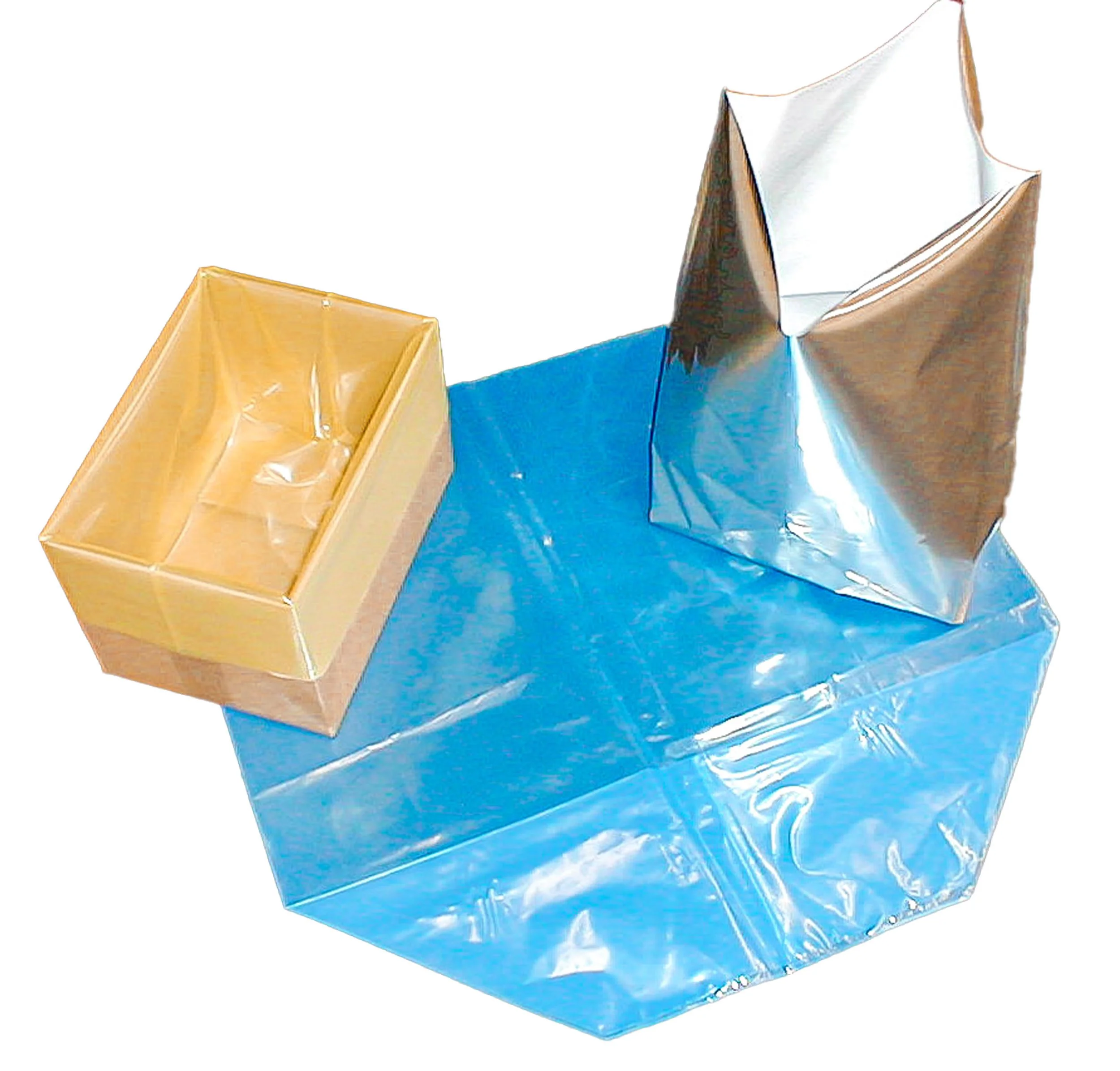

The flexible packaging industry has developed and manufactures thousands of different kinds and styles of flexible materials. From simple mono-layer polymer films to multi-layered coextruded films and multi-layered laminated materials, there are or will be flexible materials designed and structured to meet the performance specifications of every application that arises.

Some flexible packaging products use plain, un-printed materials that serve industrial, institutional, and military applications that consumers never see. Other products, seen on retail store shelves worldwide, are made from sophisticated multi-layered structures with eye-catching graphics printed in multi-colors.

Whether plain or printed, both materials are designed to keep the products or goods enclosed within them fresh and protected against environmental hazards. At the molecular level, gasses like oxygen and moisture vapor can permeate through materials with weak barrier properties and cause corrosion, and reduce shelf life. High barrier materials, especially when effectively heat sealed, can keep aroma and/or flavor inside, and damage-causing elements outside of the package.

Material structure isn’t the only factor that determines how much protection a flexible packaging product will provide. All flexible packaging materials have a “sealant layer”, or the material itself is heat sealable (i.e. mono-layer film). Using heat seals is the most effective way to convert a flat material into a 2 or 3D enclosure, but only if all heat seal settings are optimized.

Not All Heat Seals Are Created Equal

Without optimized heat sealing parameters and hermetic seals, none of the materials mentioned above will perform as designed, no matter how sophisticated the material is.

Hermetic heat seals are completely airtight. Depending on what kind of heat sealing equipment is utilized in conjunction with a film extrusion line (which is typically where poly carton liners come from) the line may or may not, produce hermetic seals.

To achieve optimally strong seals, parameters must be developed for each different sealing device that defines a specific temperature to be applied, under specific pressure, for a specific duration of time. We achieve this consistently by using equipment with calibrated controls for temperature, pressure, and time instead of manual equipment, like an iron.

Should All Heat Seals be Hermetic?

If your applications are of a critical nature such as keeping food fresh and contamination-free, keeping medical devices sterile, and preventing corrosion on high-value assets, then you need the heat seals on your packaging to be hermetic. Less critical applications such as temporary dust covers, palletized load caps, etc. can usually be serviced successfully when the heat seals are not hermetic.

Unless the purpose of the packaging is to simply keep potential contamination off of your product you really need to make sure that you choose a supplier that can produce the flexible packaging product with hermetic seals.

Case Study: Carton Liners

A past customer asked us to fix polyethylene carton liners from another supplier that were leaking. They pack a valuable powder into the lined carton and after destinations are reached if powder residue is seen outside of the liner, the product is rejected and then returned to them.

After analysis of the materials, filling process and temperature, handling and transportation methods didn’t determine the root cause of the problem, we looked at the manufacturing method of the poly liners.

Examination of the heat seals showed inconsistent width of seals, voids or non-sealed spots within a seal, “burn-outs” in areas of a seal, etc. The root cause of the leaking was determined to be poor heat seal quality.

To solve this problem we followed the seal optimization process noted above on this specific material being heat sealed on a specific piece of equipment. Through trial and error testing or making and subsequently testing the strength of seals made at varying temperatures, pressures, and times of duration we arrived at optimal settings for this particular application.

With the correct parameters in place, we were able to run new carton liners with hermetic seals- the perfect packaging solution for our new customer’s critical product. For more specifics about how we produce hermetic seals, check out our blog post on how faulty seals can create a nightmare!