Clinical Diagnostics Packaging

High barrier, instrument-ready flexible packaging designed to protect reagents, controls, and diagnostic fluids throughout automated workflows.

Precision Flexible Packaging for Automated Diagnostic Systems

In clinical diagnostics, packaging plays an active role in performance. Reagents, controls, and diagnostic fluids must move through automated systems cleanly, consistently, and without compromise.

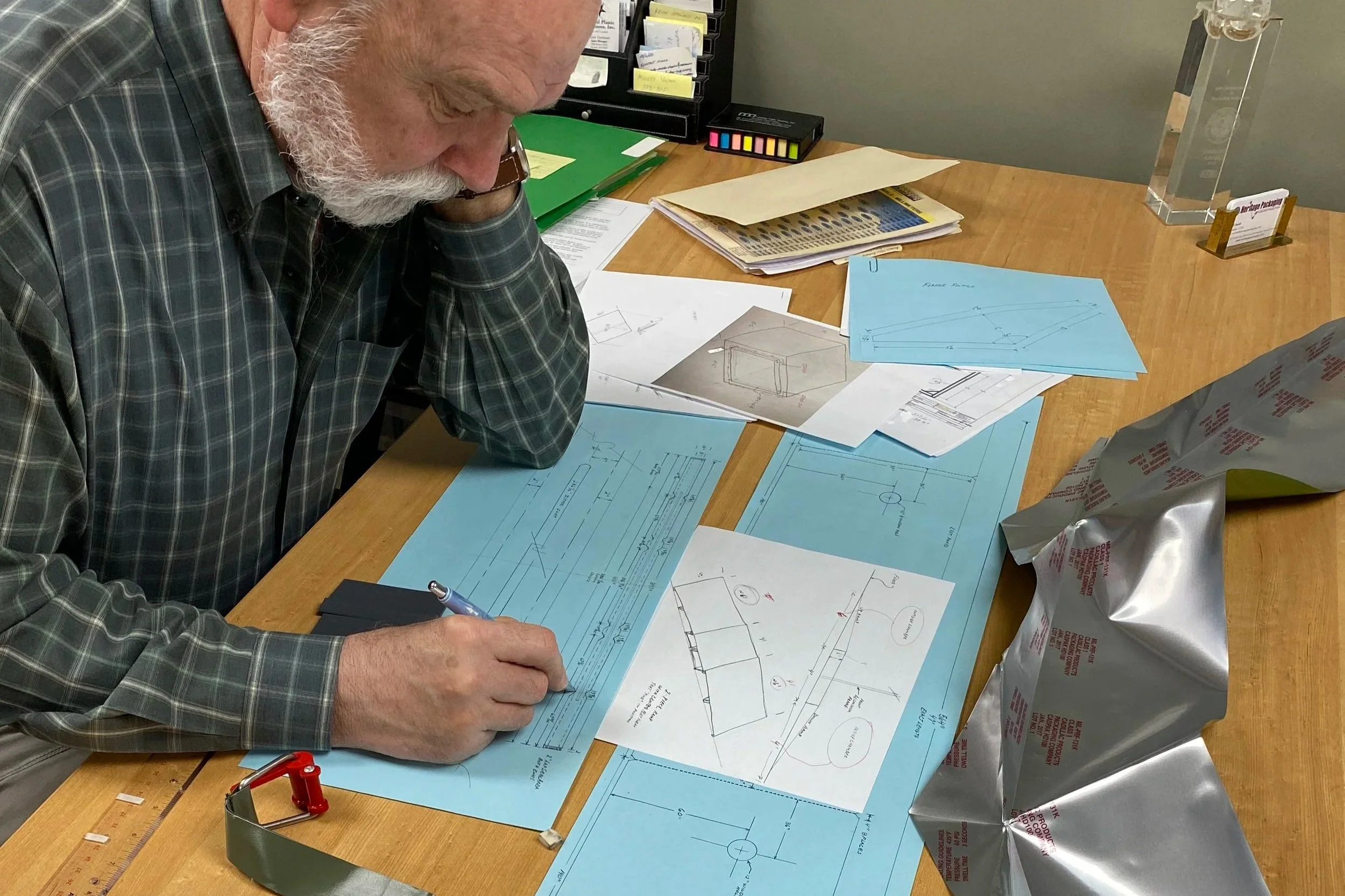

Heritage Packaging partners with clinical diagnostics manufacturers to engineer high barrier flexible packaging that integrates directly into automated platforms, protects chemical integrity, and performs reliably at scale. Our packaging is designed to function as part of your system, not just contain your product.

Who we support

We work with diagnostic manufacturers developing and producing:

In vitro diagnostic consumables

Reagent, buffer, and purge solution packaging

Controls and calibrators

Instrument integrated fluid reservoirs

Proprietary analyzer specific consumables

If your diagnostic platform relies on flexible packaging inside or alongside automated instrumentation, we understand the constraints and the stakes.

Where Our Packaging Fits in the Diagnostic Workflow

Our team designs packaging around how it is used throughout the diagnostic process. We consider the full lifecycle of your packaging, from fill to final use, to ensure consistent performance at every step.

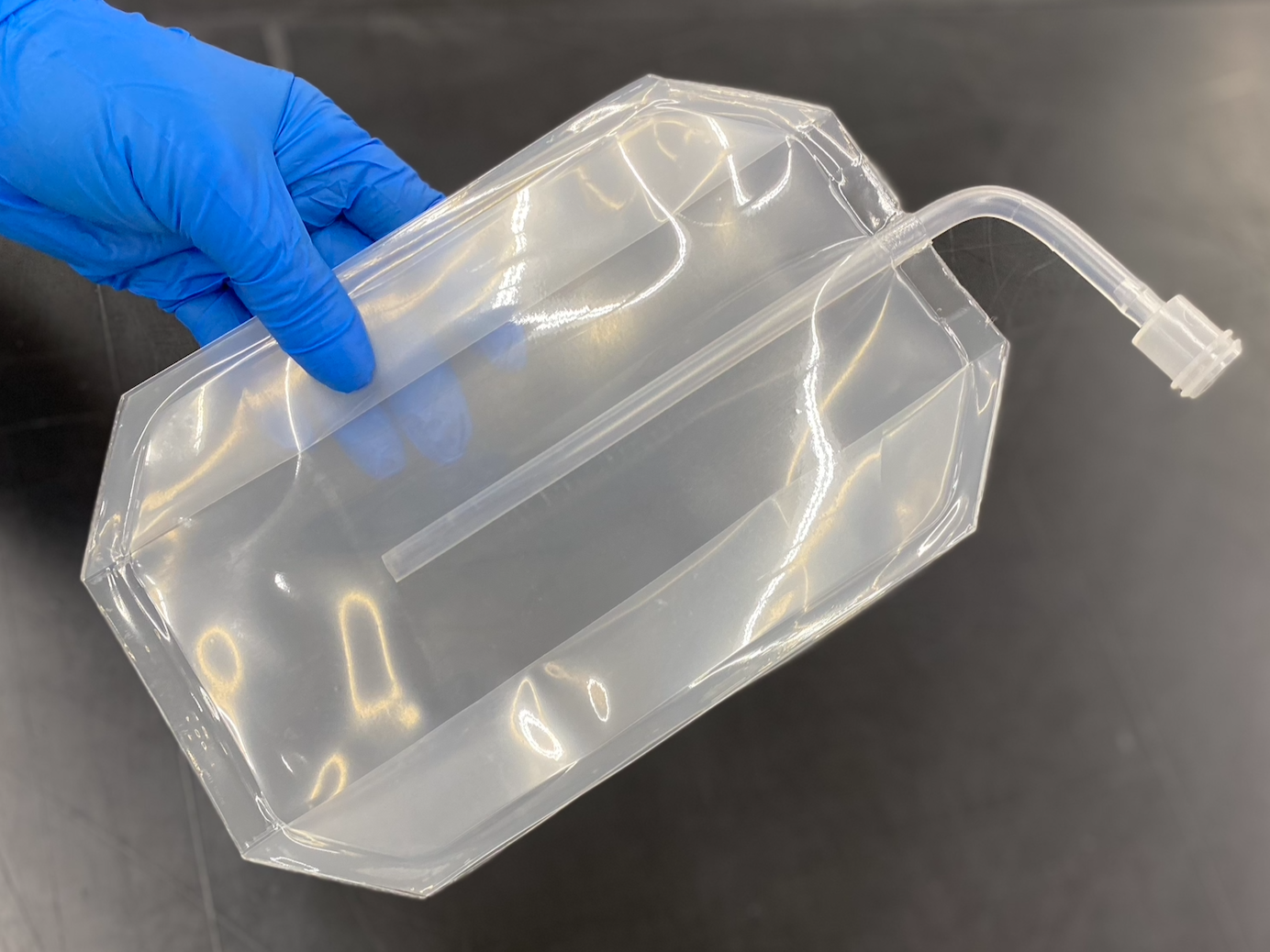

Inside the Instrument

1

Flexible pouches serve as primary fluid reservoirs housed within automated analyzers, requiring precise geometry, repeatable performance, and exact fitment placement.

Upstream and internal handling

2

Packaging supports filling, staging, interplant transport, and storage prior to use, while maintaining chemical compatibility and barrier integrity.

Secondary containment & protection

3

Engineered solutions help manage critical fluids safely during handling, transport, and storage.

Engineered Capabilities for Clinical Diagnostics

Our capabilities are built to support the demands of automated diagnostic systems.

Instrument Integrated Fitments

Molded fitments installed exactly where your analyzer requires them, including offset, recessed, angled, or non standard locations.

High Barrier Film Structures

Custom laminations selected for chemical compatibility, shelf life stability, and protection from moisture or oxygen exposure.

Precision Converting

Tight dimensional control and repeatable processes to support reliable performance inside automated platforms.

Made to Order Manufacturing

Every pouch is engineered to your platform, fluid, and operational requirements. No stock solutions. No shortcuts.

Quality & Risk Management

When packaging supports diagnostic accuracy, quality systems are essential.

Heritage Packaging operates with documented quality management processes designed to support regulated life science environments, including:

Incoming material inspection and traceability

In process and final inspection

Lot consistency and repeatability

Change control and documentation support

Our approach is proactive and detail driven, built to reduce risk and support long term program stability.

Why Diagnostic Teams Choose Heritage

Diagnostic manufacturers partner with Heritage because we:

Collaborate early in development, before designs are locked

Understand automation constraints and proprietary platforms

Engineer packaging for repeatability and long term performance

Scale seamlessly from pilot runs to ongoing production

We work as an extension of your team, focused on solving the right problem the right way.

Let’s Design Packaging That Works Inside Your System

If your diagnostic platform requires flexible packaging that integrates cleanly into automated systems and performs consistently with critical fluids, our team is ready to collaborate.